Cochin Rubbers started its successful business march in Cochin, the ‘Queen of Arabian Sea’ Right from the leap year 1980. Along its march, it happened to come across some very enterprising and encouraging customers enlightening its image to one of the eminent manufacturers of tyre retreading products. Its excellent motto, has lifted it into a large group, with a grand set up under its umbrella, especially four functioning in gulf countries. The consistent effort in product improvement has accelerated its growth.

Read MoreWe offer innovative tyre retreading solutions that reduce Carbon Footprint by 73%

Our Fast-drying solvent Oil base can withstand 100/125/159 ℃ temperature levels.

We offer Extra Strong Bonding Gum that ensures permanent adhesion.

The process constitutes the usage of synthetic rubber, natural rubber with carbon black, oil and other rubber chemicals. This combination ensures strength, durability and consistency.

High-quality Conventional Tread Rubber is manufactured with the utmost attention in extrusion making suitable for the retreading processes.

Bonding gum is manufactured with quality products to withstand the various climatic conditions befitting the retreading process carried on in any part of the world.

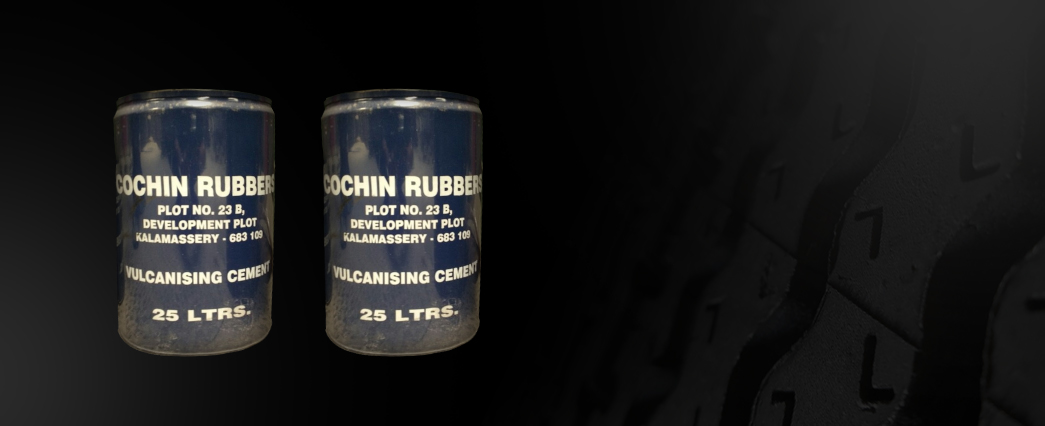

Fast-drying solvent Oil base is available at 100/125/159-degree centigrade temperature levels. Utmost care is taken to keep up its viscosity for the maximum period possible.

Cushion Gum is produced by giving maximum care and attention to its quality to make an efficient combination with conventional tread rubber.

We also manufacture Rubber Compounds - Master & Final Batches in K4 inter-mixers according to the specifications of the customers.

Nam ultricies vestibulum fringilla. Duis egestas sapien ut fringilla pharetra. Vestibulum posuere enim nec odio posuere fringilla.

Nam ultricies vestibulum fringilla. Duis egestas sapien ut fringilla pharetra. Vestibulum posuere enim nec odio posuere fringilla.

Nam ultricies vestibulum fringilla. Duis egestas sapien ut fringilla pharetra. Vestibulum posuere enim nec odio posuere fringilla.

Nam ultricies vestibulum fringilla. Duis egestas sapien ut fringilla pharetra. Vestibulum posuere enim nec odio posuere fringilla.

Nam ultricies vestibulum fringilla. Duis egestas sapien ut fringilla pharetra. Vestibulum posuere enim nec odio posuere fringilla.

Nam ultricies vestibulum fringilla. Duis egestas sapien ut fringilla pharetra. Vestibulum posuere enim nec odio posuere fringilla.

Yes. Retreaded tyres are as safe as new tyres. They are widely used across the globe in all sorts of commercial activities. They are safely used in vehicles of high importance such as school buses, ambulances, airplanes, military vans, etc.

Retread tires don’t just save you money, they offer a variety of other benefits, too

• Better for the environment—retreaded tires are repurposed and stay out of the landfill

• Extending tire life

• Don’t leave behind chunks of rubber on the road

• The obvious--saving money

The manufacturing process behind tire retreading produces safe, durable, quality tires

With proper maintenance and care, Cobber Tread Rubber will provide the same amount of service as comparable new tyres. Retreads tread life varies from the same as a comparable new tyre to 75% of a new tyre. The variables here, relative to a comparable new tyre are,

1. Retreads often start with less tread depth.

2. Due to casing conditions, the retread footprint may be smaller/narrower than the new tyre.

No. Retreading rebuilds your worn-out tyre into a new one, it is as good as a new tyre and has absolute zero propensity towards any failure.

Retreading is not some roadside job; it is a highly technical process that asks for skilled workmanship and precise technology. One must choose the right casing and the right tread pattern & rubber compound to retread a tyre.

Anyone who retreads a tyre without keeping these factors in mind builds an inferior quality retreaded tyre and such tyres can always lead to failures.

TBR is the short for Truck and Bus Radial tires, so we can see that TBR tires are mainly used for Truck and Bus vehicles, sometimes we also call TBR tire as commercial tire because the TBR tires are used for commercial vehicles. Meanwhile, the structure of TBR tire is all steel wire, so the TBR tire has better loading performance.

PCR is short for Passenger Car Radial tires, so we can see that PCR tires are mainly used for car vehicles, sometimes we also call PCR tire as car tire directly because PCR tires mainly are used for car vehicles.

PLT tire is a wider concept, which includes PCR and Light Truck tire, but here Light Truck tire is little different with above TBR tire, because the PLT tire’s structure is semi-steel, which semi-steel structure PLT has more comfortable driving experience.

OTR tire is short for Off-the-Road tire, which OTR tire mainly used for the Giant truck vehicles in mine area.

Even same tire size, the weight differs from their various patterns design.

Our Tread Rubber is designed one piece for one tire use and packed in one roll by plastic film for easy transport.

For convenience, we have marked the length, width and weight of each Precure Tread Rubber in our brochure.

1. Conventional (Hot) Retreading Process

2. Precured (Cold) Retreading Process

Conventional (Hot) Retreading

Hot Retreading involves the vulcanization of a tire in a mold at a temperature of around 150 °C. The tread and the sidewall veneer of the tire are made up of non-vulcanized rubber compounds. The shape and tread of the tire are created in the heating press.

Precured (Cold) Retreading

Pre-cure or “Cold” retreading involves vulcanization without a mould at a temperature of between 95 °C and 115 °C. The tire is put together using a pre-vulcanized tread liner (= new tread) and a non-vulcanized cushion gum layer. The bond between the carcass, the cushion gum and the precured tread is created in an autoclave. Pre-cure retreading has become fully established in the truck tires sector since the introduction of radial tires in the mid-1960s